One. Catalyst developing background

At present, that domestic waste engine oil and lubricating oil refining diesel is generally distilled by traditional ways, that is, distillation furnace plus a condenser refining. If no catalyst is added, the refined oil has a large viscosity and a high density. The surface is green and blue, and the appearance is engine oil, which can be only used as a burning oil. When engines use such diesel, it is easy to block the nozzle. There is gas catalyst in China. Add some decolorizing and adsorbent to the front end of the catalyst, and then add some decondensation catalyst, which will cause block of catalyst tower in half a month. The catalyst needs to be replaced. If it is not found in time, there is danger of explosion. This rigid gas catalyst method has caused many manufacturers with less competitiveness close down frequently. Most of the liquid catalyst sold in domestic market are a mixture of alumina and sodium hydroxide which have no function of catalyst. The refined oil is green and blue, and contains a large composition of engine oil. So such a catalysts do not have any catalyst effect, and chemical raw material must be selected according to the nature of waste engine oil. If until the end of the refining, the produced oil has a green head and has a red tail, which means the oil is not diesel, but engine oil, and also means the catalyst does not have any effect at this time. It is no difference adding or not adding catalyst. Therefore, the selective addition of liquid and gas catalyst for oil refining is increasingly in the agenda.

Two. The selection of catalyst

Catalyst is generally divided into a liquid catalyst and a gas catalyst.

It is easy safe and convenient to add a liquid catalyst into waste engine oil for refining. The liquid catalyst currently sold in the market are basically a mixture of alumina and sodium hydroxide, and the effect on product is not obvious. This is a deep understanding of the traditional oil refining factories. Using alumina refining to the middle and the late stage always come out of engine oil instead of diesel. The surface of the oil is green and blue. The oil color is red and the smell is not pure. This is a common problem in domestic oil refining enterprises.

The gas catalyst is a catalyst added to the gas catalyst tower. If the catalyst is used improperly, the oil yield will be low and the poisoning is easy to be inactivated. The pipeline will block, and there is a danger of explosion.

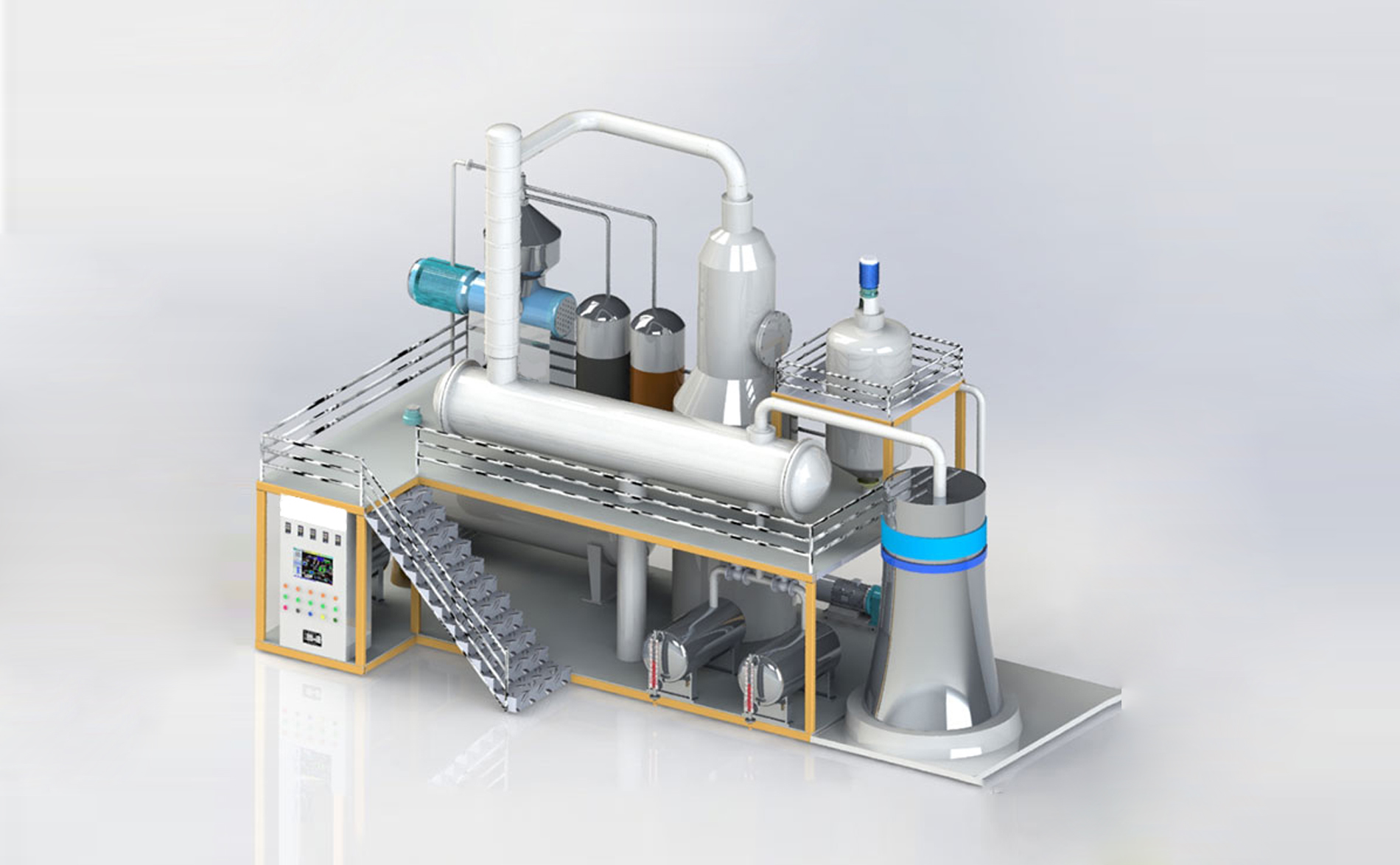

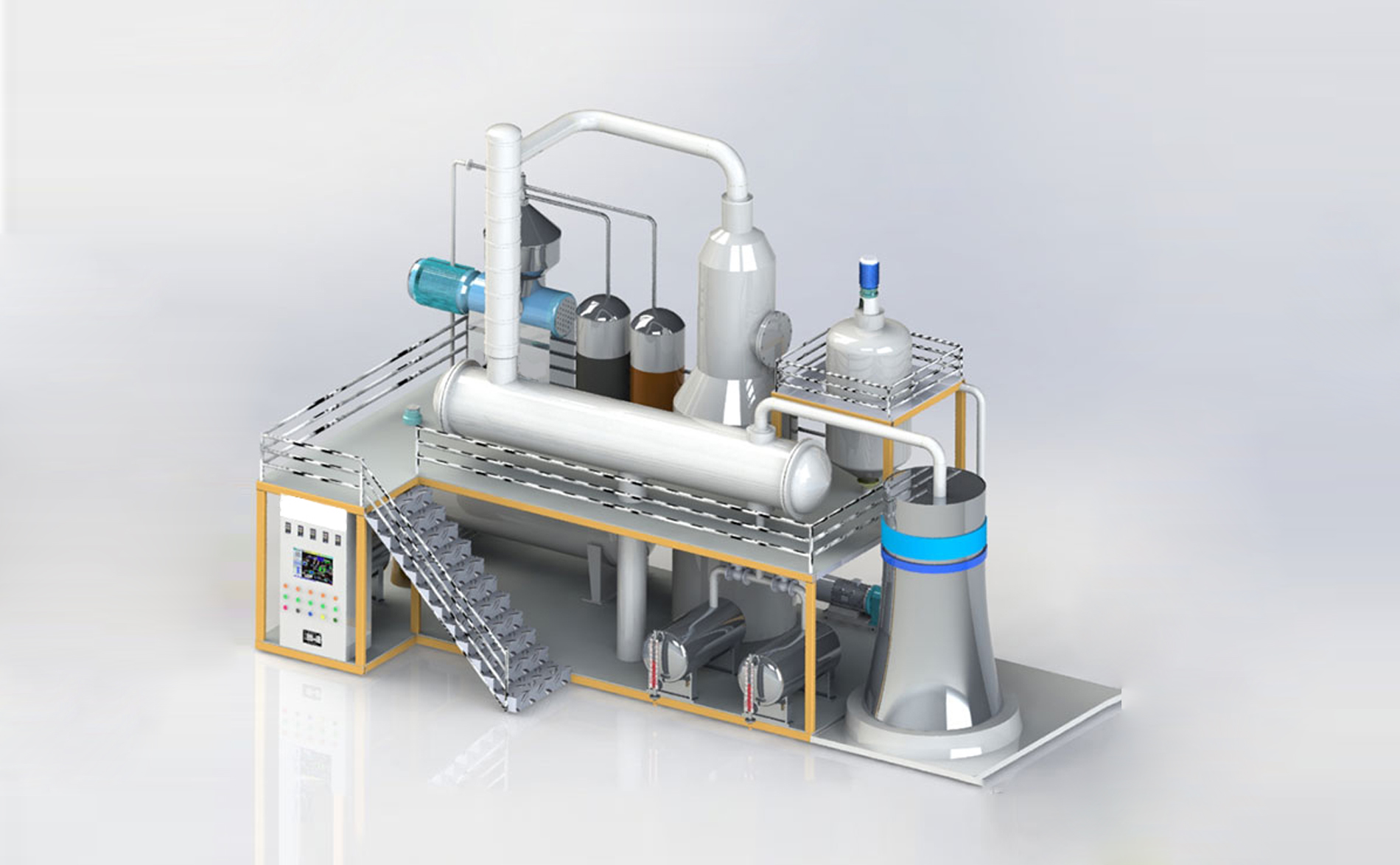

Some companies have developed a high-performance liquid phase cracking catalyst and gas phase catalyst which is not easy to block for the refining of diesel from waste oil and gear oil. The catalyst can significantly shorten one-third of the refining time, and greatly decrease the refining temperature, saving cost of coal. Moreover, the selectivity to the product diesel is high, and the catalyst has the advantage of producing less gasoline and more diesel.

And the introduced waste engine oil special high-activity catalyst, is used for liquid phase catalysis and gas phase catalysis, ensuring safety and catalysis effect. And it ensures that the waste engine oil totally cracks from head oil to the end of oil refining, without composition of green head engine oil, and the oil comes out does not have any odor. The color is clean and not turbid, and it is close to water white. In the process of heating, even if the heating speed is fast, the oil comes out is light yellow, which does not affect the cracking quality.