The production of modern lubricants requires both good quality base oils, good quality additives and excellent additive formulations.

It has been demonstrated in the production practice of natural lubricating oils that the quality of the lubricating oil depends both on the additive and on the base oil. The deeper the refined depth of the base oil, the better the sensitivity to the additive. However, from an economic point of view, it is not the deeper the refined depth of the base oil. In order to achieve the same product quality, it is to deepen the refining depth of the base oil or increase the amount of additives. Depending on the cost, although deepening the refining depth can reduce the amount of additives, if the cost of the additive saved is insufficient to compensate for the increase in the cost of refining, It is not cost effective, so there is a question of choosing the appropriate refinement depth.

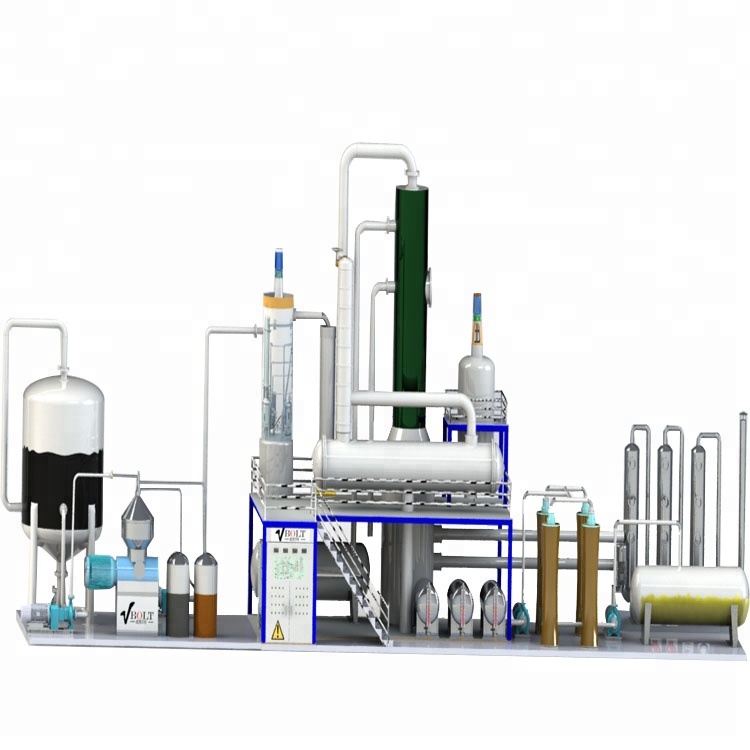

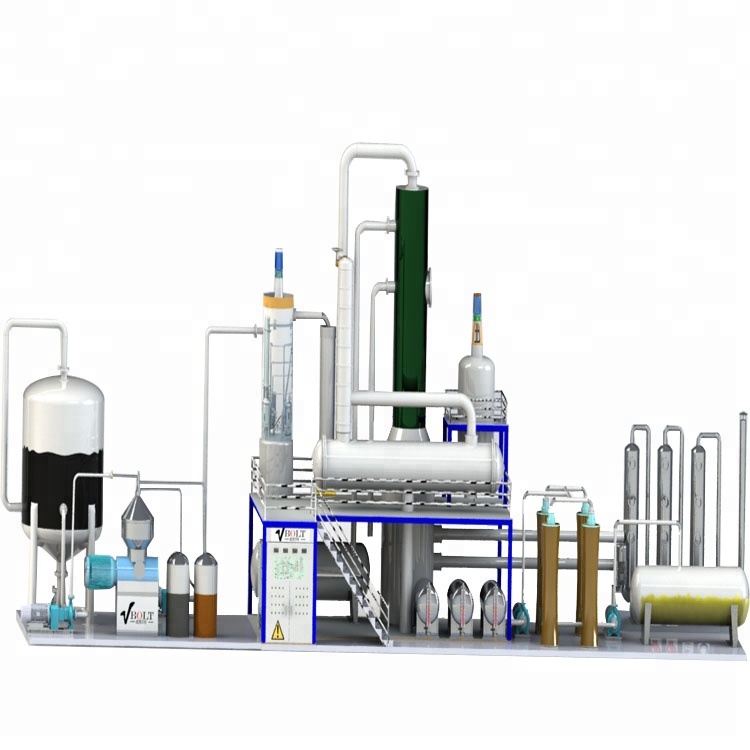

A large amount of research and practice has formed the specifications of the base oil, which reflects the reasonable refinement depth that should be. The recycled base oil produced by the waste lubricating oil recycling plant should also reach this specification or close to this specification in order to produce high-quality high-grade lubricating oil, but the recycling of the waste lubricating oil has its own particularity, and it is not necessary to fully adhere to the specifications of the natural oil base oil.

Practice has proved that after the recycled base oil reaches or approaches the quality level of the natural oil base oil, the formula for the natural lubricating oil is selected for the reclaimed oil to produce a high-grade product similar in quality to the natural lubricating oil. Therefore, in the daily production of waste lubricating oil recycling plant, in order to produce high-quality reclaimed lubricating oil products, it is mainly necessary to control the production process conditions and produce high-quality regenerated base oil.

For the reclaimed oil used in the unit, since it is often repurified or re-refined, it is not a regenerated base oil but a purified regenerated lubricating oil. It also retains a large number of original additives in the plant. Such reclaimed oil can be replenished by adding appropriate amount of additives, or mixed with new oil in a certain ratio. In daily production, each tank is also sampled and analyzed, and the production is controlled according to the quality control standards adopted by itself.

The quality control in the production of recycled base oil and lubricating oil is an analysis of physical and chemical indicators, which are divided into daily analysis and factory analysis. Daily analysis is only used to control the daily production of the project, the factory analysis is the sampling analysis of the finished oil tank, generally for the full analysis, in addition to the agreement to allow the reduction of some projects, generally in accordance with national standards or industry standards .

The waste lubricating oil recycling plant will also produce a small amount of by-product diesel. Generally, the refined regenerative diesel is close to the specification of No. 0 diesel. The necessary analysis should be carried out before the sale. Although it is not necessary and necessary to analyze the cetane number, it should be physicochemical. The indicator calculates the cetane number index.