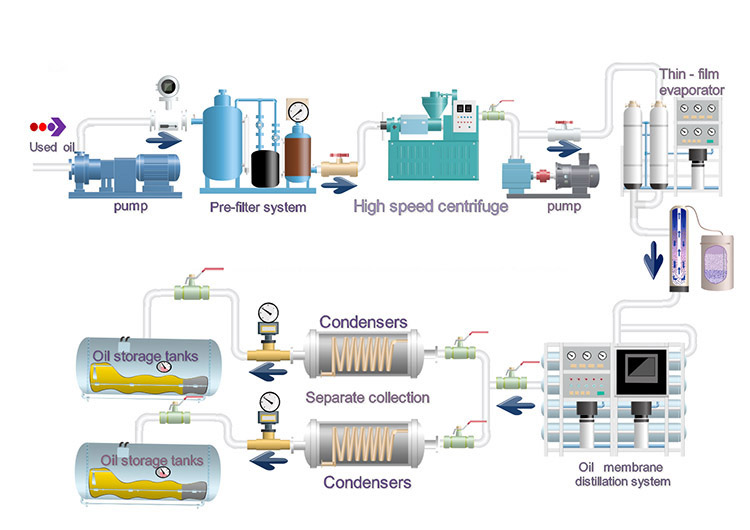

Waste motor oil refining diesel steps:

- Praesent elementum molestie metus, vitae faucibus odio euismod vitae.

Distillation The waste engine oil obtained by sedimentation treatment to remove the precipitate was placed in a distillation flask. The distillation apparatus is installed and heated to carry out atmospheric distillation. The gasoline is distilled at 180 ° C, and the fraction of 180 to 360 °C is diesel, leaving the engine oil. If it is known that there are no impurities such as gasoline and diesel in the waste oil, this step can be omitted.

Pickling Put the sedimented and distilled oil into a large beaker, heat it to 35 ° C, and slowly added to the concentrated sulfuric acid of about 6 to 8% of the oil volume (added in 30 minutes) with stirring.At this time, the concentrated sulfuric acid reacts with the colloidal and asphaltic impurities in the used oil. In order to remove these sulfonated impurities, a 10% caustic soda solution containing 1% by volume of the oil is added to act as a coagulant to accelerate the stratification of the impurities.After adding alkali, stirring for 5 minutes, and standing for a while, there is obvious stratification, the upper layer of oil is yellow-green, and there are no impurities such as black particles.

Alkaline washing This step is to remove the organic acid from the waste engine oil and neutralize the sulfuric acid remaining during pickling.The acid-washed engine oil was added to another beaker, heated to 90 ° C, and sodium carbonate powder of 5% by weight of the oil was slowly added under stirring, and the acidity and alkalinity of the oil were checked after 20 minutes.Take two tubes, each adding 1 ML of distilled water, one of which adds 2 drops of phenolphthalein reagent and the other adds 2 drops of methyl orange reagent.Then add 1 ML of the oil sample to the two tubes and shake for 3 minutes. If the color of the aqueous layer in the two tubes does not change, the oil is neutral, and the oil should be clear.

Filtration Industrial filtration with an oil filter. Household oil can be repeatedly filtered 2 to 4 times with 4 to 6 layers of silk cloth, Then get the qualified diesel.

[Explanation]

If you know the various impurity components in the waste oil, you can adjust the above steps according to the actual situation. For example, the engine oil contains only solid impurities such as metal chips, and it may be separated by a sedimentation method. If only oil, diesel, etc. are mixed into the oil, the regenerated diesel can be obtained by distillation. If only the oil is oxidized and deteriorated, it is only necessary to remove impurities such as organic acids by pickling or caustic washing.